MIL-PRF-27G

a.

The duration of visible flame does not exceed 3 minutes after removal of the applied flame.

b.

There is no explosion, nor any violent burning which results in an explosive-type flame.

c.

There is no dripping of flaming material from the transformer or inductor under test.

3.26 Life. When the transformers and inductors are tested as specified in 4.7.23, there shall be no evidence of

physical or electrical damage as indicated by an open circuit (a break in the continuity of any electrical circuit within the

transformer or inductor being tested) or short circuit occurring within the transformer or inductor (such as shorted turns

or faulty insulation between layers, turns, windings, windings and case or core, or windings and shield). In addition,

transformers and inductors shall meet the following requirements:

a.

Insulation resistance shall be as specified in 3.13c.

b.

Dielectric withstanding voltage (at atmospheric pressure) shall be as specified in 3.11.

c.

Induced voltage shall be as specified in 3.12.

The electrical characteristics shall remain within the tolerance or limits specified (see 3.1).

3.27 Fungus. All external materials shall be non-nutrient to fungus growth or shall be suitably treated to retard

fungus growth. The manufacturer shall certify that all external materials are fungus resistant (see 4.7.24) or shall

perform the test specified in 4.7.24. There shall be no evidence of fungus growth on the external surfaces.

3.28 Burn-in (Product level T only). When transformers and inductors are tested as specified in 4.7.5 there

shall be no leakage of filling material and no evidence of physical damage such as cracks, bursting or bulging of the

case or corrosion affecting the mechanical or electrical operation.

3.29 Radiographic Inspection (Product level T only). When transformers/inductors are tested in accordance

with 4.7.25, they shall exhibit no evidence of defects listed in Appendix B

3.30 Marking. The transformers and inductors shall be marked with the military part number, manufacturer's part

number, name or identifier, or CAGE code, source code terminal identification (circuit diagram where space permits),

date code, and lot symbol (if other than date code) in accordance with method I of MIL-STD-1285. The marking may

be applied to more than one side of the case if the required marking necessitates more space than is available on the

one side. Where the surface areas are insufficient for all of the required information, as many as possible of the

markings shall be applied using the order of priority as listed above. Markings shall remain legible after all tests

(except for flammability). Any markings of a classified nature shall not be included. The type designation shall not be

marked on the unit unless otherwise specified (see 3.1). As specified (see 3.1), use of tags or labels are allowed when

part marking surface is insufficient for full marking.

3.30.1 Terminal identification. Unless otherwise specified (see 3.1), terminals shall be identified by

appropriate numbers or, where space does not permit numbering, by color coding in accordance with table III.

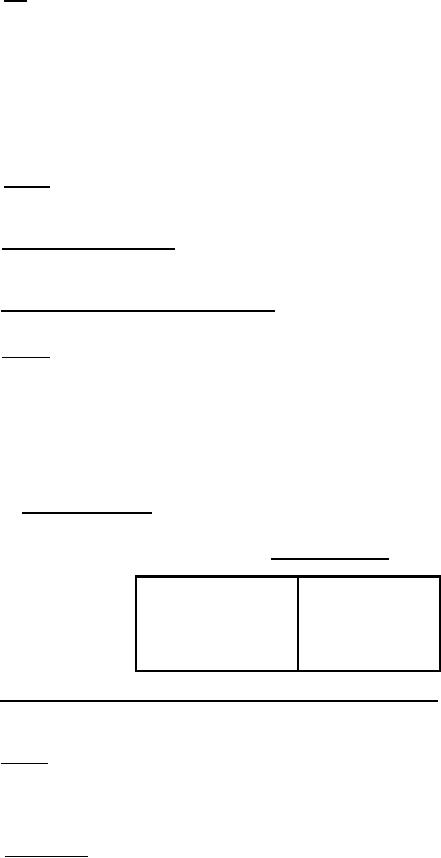

TABLE III. Terminal color code.

Black (ground) - 0

Green

---5

Brown - - - - - - - 1

Blue

--6

Red - - - - - - - - - 2

Violet

--7

Orange - - - - - - 3

Gray

---8

Yellow - - - - - - 4

White

---9

3.31 Recycled, recovered, or environmentally preferable, or biobased materials. Recycled, recovered, or

environmentally preferable materials should be used to the maximum extent possible provided that the material meets

or exceeds the operational and maintenance requirements, and promotes economically advantageous life cycle costs.

3.32 Pure tin. The use of pure tin, as an underplate or final finish, is prohibited both internally and externally. Tin

content of, transformer or coil, components and solder finish shall not exceed 97 percent, by mass. Tin shall be alloyed

with a minimum of 3 percent lead, by mass (see 6.21). Use of lead-free, tin alloy high temperature solders for internal

connections requires approval by the qualifying activity. The tin content of lead-free high temperature solders shall not

exceed 97 percent by mass. In addition, completed devices shall not be re-plated.

3.33 Workmanship. The transformers and inductors shall be processed in such a manner as to be uniform in

quality and shall meet the requirements of 3.3, 3.4, and 3.30, as applicable, and shall be free of defects that will affect

life or serviceability.

7

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business