MIL-PRF-27G

4.7.6.1 Solder bath method (for Surface Mount Devices and printed circuit terminals). Transformers and inductors

shall be tested in accordance with method 210 of MIL-STD-202. The following details shall apply:

a.

Special preparation of specimen - Sample units shall not have been soldered during any of the previous

tests.

b.

Depth of immersion in the molten solder - To a point 1/4 inch from the nearest insulating material or to

one-half the exposed length of the terminal, whichever point is closer to the insulating material.

Test condition B (260°C ±5°C; immersion, 10 ±1 seconds).

c.

d.

Examination after test - The transformers and inductors shall be visually examined and there shall be no

seepage of the impregnant, loosening of the terminals or other mechanical damage. The windings of

transformers or inductors shall be checked for continuity. The transformer or inductor shall remain

under standard atmospheric conditions for 15 minutes before final measurements are made.

4.7.6.2 Soldering iron method (for all other terminal types). The test shall be performed on all solder terminals

attached to the transformer or inductor. The solder shall conform to J-STD-004, composition Sn60Pb40A or

Sn63Pb37A. The flux shall conform to J-STD-006, form W and flux symbol A, flux percentage symbol 6 or 7. The iron

and solder shall be applied to the termination. Tinning for free flowing of the solder with proper wetting shall be evident.

The transformer or inductor under test shall remain under standard atmospheric conditions for recovery for fifteen

minutes, before final measurements are made.

a.

Special preparation of specimen - The surface shall be smooth and properly tinned and the solder

terminations shall not have been soldered during any previous test.

b.

Examinations after test - In accordance with 4.7.6.1.

c.

Test condition A ( 350°C ±10°C).

d.

Point of application of soldering iron - 1/4 inch from the nearest insulating material or to one-half the

exposed length of the terminal whichever point is closer to the insulating material.

4.7.7 Terminal strength (see 3.9). Transformers and inductors shall be tested as specified in 4.7.7.1 to 4.7.7.3.2

inclusive, as applicable. After each test, the terminals shall be examined for loosening and rupturing, and other

mechanical damage. Unless otherwise specified, all terminals on each test sample shall be subjected to the following

tests, up to a maximum of four identical terminals per sample.

4.7.7.1 Pull.

4.7.7.1.1 Solid-wire and insulated wire lead terminals (other than printed circuit terminals). Transformers and

inductors shall be tested in accordance with method 211 of MIL-STD-202. The following details shall apply:

a.

Test condition - A.

b.

Points of measurement - A force shall be applied in the direction of the axis of termination and shall be

increased gradually until the magnitude specified in table X is reached and shall be maintained for a

period of 5 to 10 seconds.

4.7.7.1.2 Solder terminals. Transformers and inductors shall be tested in accordance with method 211 of MIL-

STD-202. The following details shall apply:

a.

Test condition - A.

b.

Points of measurement - A force as specified in table X shall be applied to each terminal at the point

where the lead from the external circuit connects to it. The force shall be applied in the weakest

direction of the terminal, and shall be increased gradually to the specified magnitude and shall be

maintained at that value for a period of 5 to 10 seconds.

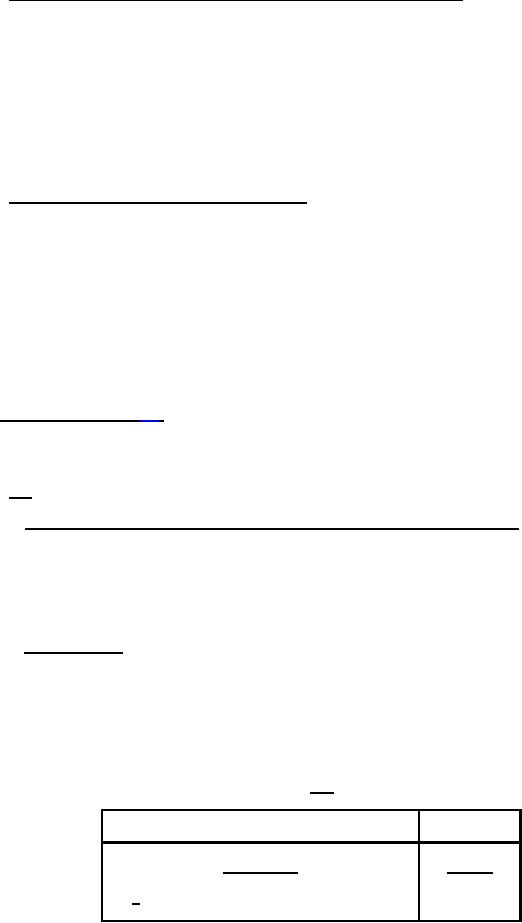

TABLE X. Pull.

Cross-sectional area of electrode at its smallest

point at which lead from external circuit connects

Force

Circular mils

Pounds

<2,000 - - - - - - - - - - - - - - - - - - - - - - - - - - - -

2.0

>2,000 - - - - - - - - - - - - - - - - - - - - - - - - - - - -

5.0

130p18" style="font-size:11px">18

Downloaded: 2014-09-24T13:27Z

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business