MIL-PRF-27G

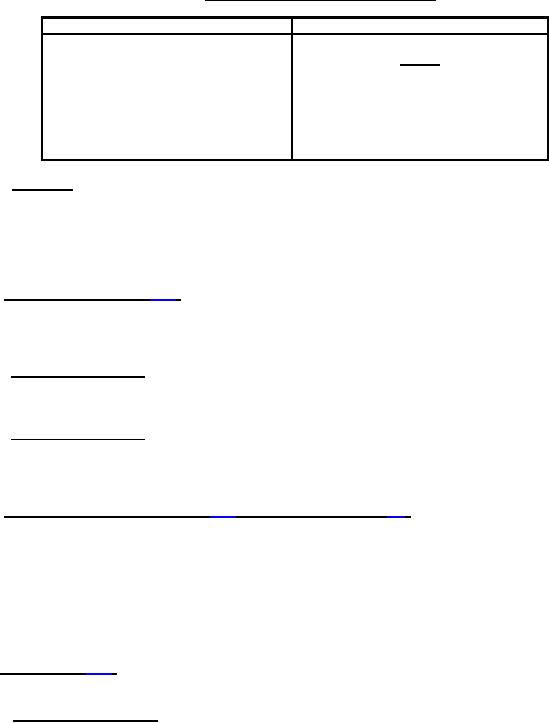

TABLE XV. Brass spacers for temperature-rise test.

Mounting screw size

Brass spacer (diameter and length)

Inches

.38 x 3.00

.138

.56 x 3.00

.164

.69 x 3.00

.190

.81 x 3.00

.250

1.62 x 3.00

.375

.500

1.75 x 3.00

4.7.13.3 Method III. Two transformers or inductors shall be mounted as specified in 4.7.13.2 and shall be placed

side by side in a duct, with the longer sides parallel to the direction of air flow supplied by a blower rated at 50 cubic

feet per minute. The blower shall be placed approximately 3 feet from the sample units. The distance between the two

sample units and the distance between the sample units and the sides of the duct shall be 15 ±2 percent of the shorter

side. Noncombustible baffles shall be used to adjust the duct to proper size. The air temperature within the duct shall

4.7.14 Corona discharge (see 3.16). When specified (see 3.1), transformers and inductors shall be tested in

accordance with 4.7.14.1 or 4.7.14.2, as applicable. The oscilloscope used for this test shall have the sensitivity set at

approximately 0.1 volt peak-to-peak per inch and shall have a reasonably uniform response up to 200 kilohertz. An

oil-filled unit may be tested at any angle of inclination unless an angle is specified (see 3.1).

4.7.14.1 Intrawinding insulation. When specified (see 3.1), transformers and inductors shall be tested using circuit

1 of figure 8. The corona peak test voltage shall be applied under pressures equivalent to pressures ranging from sea

level to the altitude specified (see 3.1) and shall be 130 percent of the applicable peak terminal voltage.

4.7.14.2 Interwinding insulation. When specified (see 3.1), transformers and inductors shall be tested using circuit

2 or 3 of figure 8, as applicable. The test voltages shall be applied under pressures equivalent to pressures ranging

from sea level to the altitude specified (see 3.1), in the same manner as specified for the dielectric withstanding voltage

test (see 4.7.9). The peak of the corona test voltages shall be 130 percent of the working voltages.

4.7.15 Salt atmosphere (corrosion) (see 3.17). When specified (see 3.1). Transformers or inductors shall be

tested in accordance with method 101 of MIL-STD-202.

a.

Test condition - B.

b.

Salt solution concentration - 5 percent.

c.

Examination after exposure - Transformers and inductors shall be thoroughly washed. The

temperature shall not exceed 38°C. The transformer or inductor shall be placed in an oven

maintained at 50°C ±3°C for a period of 24 ±4 hours. At the end of this period, the transformers and

inductors shall be removed from the oven and examined for corrosion.

4.7.16 Vibration (see 3.18). Transformers and inductors shall be tested in accordance with 4.7.16.1 or 4.7.16.2, as

applicable.

4.7.16.1 Vibration, low frequency. Transformers and inductors shall be tested in accordance with method 201 of

MIL-STD-202. The following details and exceptions shall apply:

a.

Tests and measurements prior to vibration - Not applicable.

b.

Method of mounting - Transformers and inductors shall be rigidly mounted by their normal mounting

means.

c.

Procedure - When specified (see 3.1), transformers and inductors shall be placed in a test chamber

and preheated to the specified maximum ambient temperature for the class (see 3.1) plus one-half the

allowable temperature rise. Vibration in each plane shall begin 5 minutes after removal from the test

chamber.

d.

Apparatus:

(1)

For transformers and inductors weighing 10 pounds or less - May be tested on a horizontally-

or vertically vibrating machine. Units, which are normally supported by their wire-lead

terminals, shall be mounted and soldered to rigidly supported terminals, so placed that the

length of each wire-lead terminal shall be approximately .625 inch. Units, which are mounted

to printed circuit boards, may be supported during vibration by cementing the units to a

vibration fixture or restraining the bodies of the units in casting wax, or other suitable means.

138p26" style="font-size:11px">26

Downloaded: 2014-09-24T13:27Z

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business