MIL-PRF-15305F

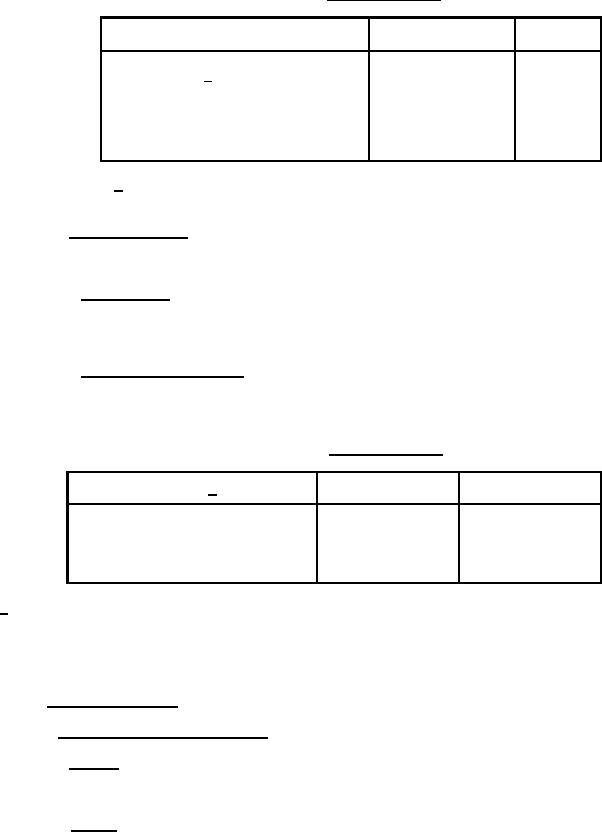

TABLE VI. Group A inspection.

Requirement

Method

Inspection

paragraph

paragraph

Thermal shock 1/ - - - - - - - - - - - - -

Operating torque (when applicable)

Electrical characteristics (initial) - - - -

Visual and mechanical examination

(external) - - - - - - - - - - - - - - - - - - -

3.22 and 3.24

1/ Measurement after thermal shock, not applicable.

4.5.1.3 Group B inspection. Group B inspection shall consist of the examinations and tests specified in table VII ,

in the order shown, and shall be made on sample units which have been subjected to and have passed group A

inspection.

4.5.1.3.1 Sampling plan. A sample of parts shall be randomly selected from each inspection lot in accordance with

table V. If one or more defects are found, the lot shall be rescreened and defects removed. After screening and

removal of defects, a new sample of parts shall be randomly selected in accordance with table V. If one or more

defects are found in the second sample, the lot shall be rejected and shall not be supplied to this specification.

4.5.1.3.2 Disposition of sample units. Sample units which have passed all the group B inspection may be

delivered on the contract or purchase order, if the lot is accepted and the sample units are still within specified

electrical tolerances and meet the requirements for visual and mechanical inspection. The leads of these sample units

shall also be clean, smooth and free from any foreign particles.

TABLE VII. Group B inspection.

Requirement

Method

Test 1/

paragraph

paragraph

Electrical characteristics (initial)

Inductance - - - - - - - - - - - - - - - - -

Q ------------------------

1/ If the manufacturer can demonstrate that these tests have been performed five consecutive times with zero failures,

these tests can be performed on an annual basis, with approval of the qualifying activity. If the interface, physical

dimension, or processing of the part is changed, or of there are any quality problems or failures, the qualifying activity

may require resumption of the original test frequency. A change in test frequency does not relieve the manufacturer from

meeting the test requirements in case of dispute.

4.6 Methods of inspection.

4.6.1 Visual and mechanical examination.

4.6.1.1 External. Coils shall be examined to verify that their weight, materials, external design and construction,

physical dimensions, marking, and workmanship are in accordance with the applicable requirements (see 3.1, 3.3 to

4.6.1.2 Internal. Coils shall be disassembled and/or dissected and examined to verify that the materials, internal

design, construction, and workmanship are in accordance with the applicable requirements (see 3.1, 3.3 to 3.3.5

inclusive, and 3.22).

10

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business