MIL-PRF-15305F

TABLE IV. Qualification inspection Continued.

Inspection

Requirement

Method

Number of

paragraph

paragraph

Sample units to be

Inspected 4/

Group V

Fungus 3/

---------------------

2

Group VI

Solderability 1/ (both leads) - - - - - - - -

6

Resistance to solvents 1/ - - - - - - - - - -

4

Flammability (use 3 units for Solderability) -

(3)

1/ The units shall be clean units that have not been subjected to any other test.

2/ After the overload test is performed, a period of 24 hours shall elapse prior to taking electrical characteristics

(final) measurements.

3/ The fungus requirement is either by certification or performance.

4/ Combined submission will be in accordance with the appendix (see A.2.1.2)

4.5 Conformance inspection.

4.5.1 Inspection of product for delivery. Inspection of product for delivery shall consist of groups A and B

inspection. Group B inspection for preparation for delivery is not required when the qualifying activity has allowed

group B testing to be performed annually (see table VII).

4.5.1.1 Inspection lot. An inspection lot shall consist of all the coils of the same style and made of the same core

material and of the same specification sheet (or Military Standard sheet) produced under essentially the same

conditions, and offered for inspection at one time. The manufacturer may combine coils of different inductance values

and inductance tolerances. The inductance value shall be equally representative of the production lot for that period.

4.5.1.2 Group A inspection. Group A inspection shall consist of the examination and tests specified in table VI, in

the order shown.

4.5.1.2.1 Sampling plan. A sample of parts shall be randomly selected from each inspection lot in accordance with

table V. If one or more defects are found, the lot shall be rescreened and defects removed. After screening and

removal of defects, a new sample of parts shall be randomly selected in accordance with table V. If one or more

defects are found in the second sample, the lot shall be rejected and shall not be supplied to this specification.

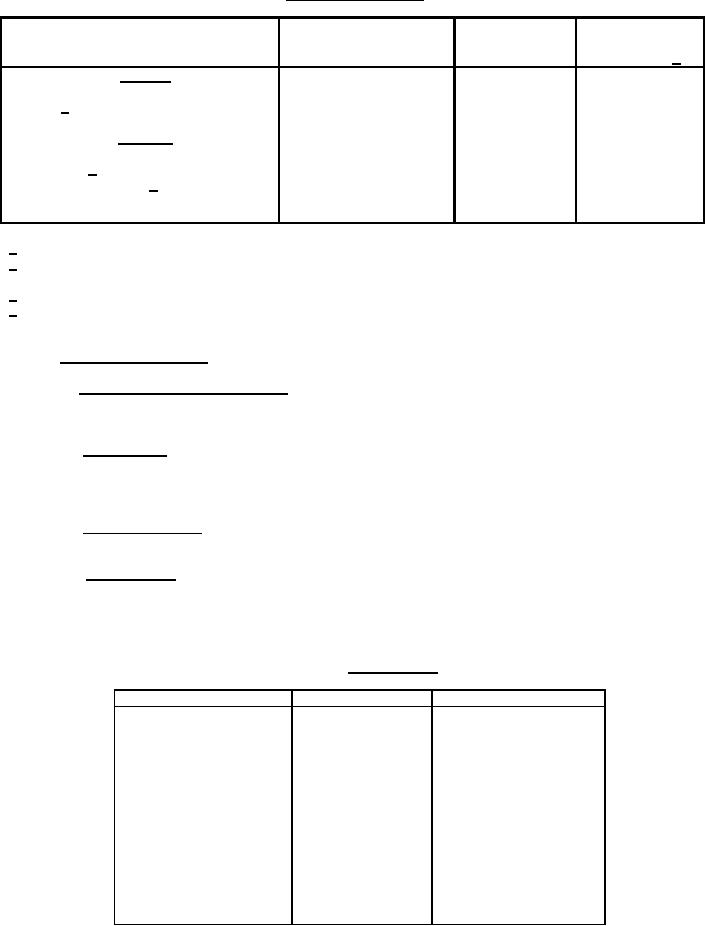

TABLE V. Sampling plan.

Lot size

Group A

Group B

1 to

5

100 percent

100 percent

6 to

13

100 percent

5

14 to

50

13

5

51 to

90

13

7

91 to

150

13

11

151 to

280

20

13

281 to

500

29

16

501 to

1,200

34

19

1,201 to

3,200

42

23

3,201 to

10,000

50

29

10,001 to

35,000

60

35

35,001 to 150,000

74

40

150,001 to 500,000

90

40

500,001 and over

102

40

9

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business